Individual orders

Are you looking for a contractor for bulk orders? Get in touch with us!

Mielec

Dębica

Dębica

+48 881 200 461

Mielec

+48 570166051

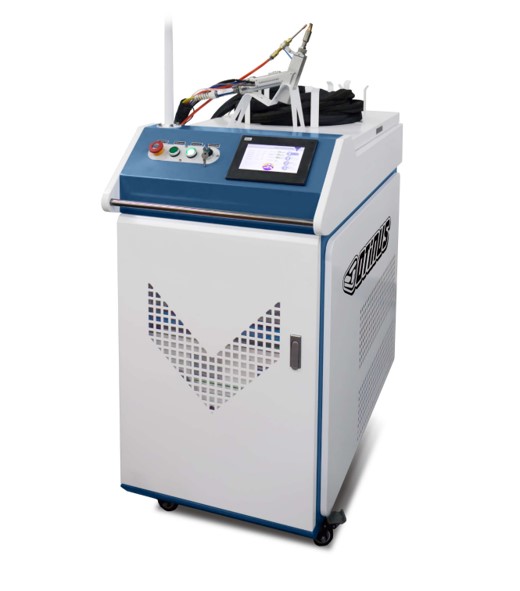

Laser welding is an innovative technique for processing materials. It is designed for welding various types of materials. It is characterized by detailed accuracy, high speed and smooth, flawless welds.

Laser welding works on the principle of radiation, which heats the surface of the workpiece. The heat on its surface is dissipated inwards by the thermal conductivity of the material. This causes the inside of the material to melt and form a weld when cooled.

Currently, we have two laser welding machines in our machine park:

Why choose laser welding?

We invite you to contact us!

Individual orders

Are you looking for a contractor for bulk orders? Get in touch with us!